Country elevators and grain terminals, although similar in concept, handle grain in a similar way but with fundamentally different goals.

Country Elevators

In the classic country elevator model, an elevator will typically purchase grain from the local farmer, and provide a variety of services to support that process, including grain split accounting, storage, cleaning and/or drying, and sales of crop input supplies. The fundamental business model is built around grain purchase from the originating farmer, with grain price, value-added services, and longstanding customer relationships differentiating elevators. Many elevators offer the ability to deliver against unpriced contracts, such as basis contracts or deferred price/price later contracts as well as open storage. In addition to offering merchandising contracts, grain elevators may also make money by increasing the quality of the grain through grain blending or superior bin management.

Country elevators need a CTRM (Commodity Trade Risk Management system) and grain management software that allows them to maintain a position and engage in risk hedging. Their key goal is to buy grain at the best price possible while maintaining a strong relationship with the farmer, and reselling that grain for a profit.

Terminal Storage

Grain terminals tend to be larger and centrally located near ports or other transportation hubs. They offer large storage capacity, and transloading options, such as switching from truck to rail, barge, or vessel. Although grain terminals may purchase grain, typically the emphasis is on storing the grain rather than purchasing it. They will charge discounts for wet grain or other quality factors and may charge drying, but the emphasis is typically more on storage than purchase price. The purpose of grading the grain at scale ticket time is to record the quality of the grain deposited so that the same approximate quality can be withdrawn at a later date.

Elevator Storage

Storage is typically handled differently in a country elevator versus a terminal operation. In a country elevator, grain is usually brought to the elevator to be purchased, and grain storage fees may be charged in order to encourage a purchase commitment. In these cases, grain will often be charged on a load-by-load basis, with storage being charged on specific deliveries of grain until the grain is settled.

In a terminal operation, storage is the goal rather than an ancillary part of the operation, with the commodity being stored until it can be sold or transloaded to another facility. As there is a large quantity of grain involved, storage is typically computed on a daily basis, based on the customer’s end-of-day balance at the terminal. The most typical cycle will involve the grain being dropped off at a facility, stored for a period, and then shipped out, often via different transport modes. For example, you might drop off 200 truckloads of grain, which you then ship via a compartment on an ocean-going vessel. The terminal would make money by charging for the initial elevation and drying of the grain, and the storage of the grain, and perhaps an unloading fee when the grain is shipped.

Customer to Customer Transfers

Sometimes the sale and purchase of the grain might actually be between two of the terminal’s customers. In this case, the ownership of the grain will change, but there is no accounting impact from the terminal's point of view, in that they are still responsible for delivering the same quantity of stored grain, albeit for a different customer.

This transaction is similar to a transfer between bank accounts, where the bank is recording the change of balance between two customers without otherwise participating in the transaction.

Internal “House Account”

Many large agribusinesses own a network of elevators as well as one or more terminal facilities. Typically, grain elevators and terminal operations will be treated as two separate business lines, with a separate profit and loss for each facility and business. The grain elevator software and the terminal management software need to work together in terms of logistics and shipments, but keep a clear delineation of ownership and the profit due to the merchandising of the grain.

When a large agribusiness owns a terminal, the terminal might actually store their own grain. This is typically accomplished by setting up a “house account” that treats your internal purchases, sales, and transfers largely as if you were a third-party customer. The advantage of this approach is it allows you to separate the margin from your grain procurement business from the margin on your terminal business.

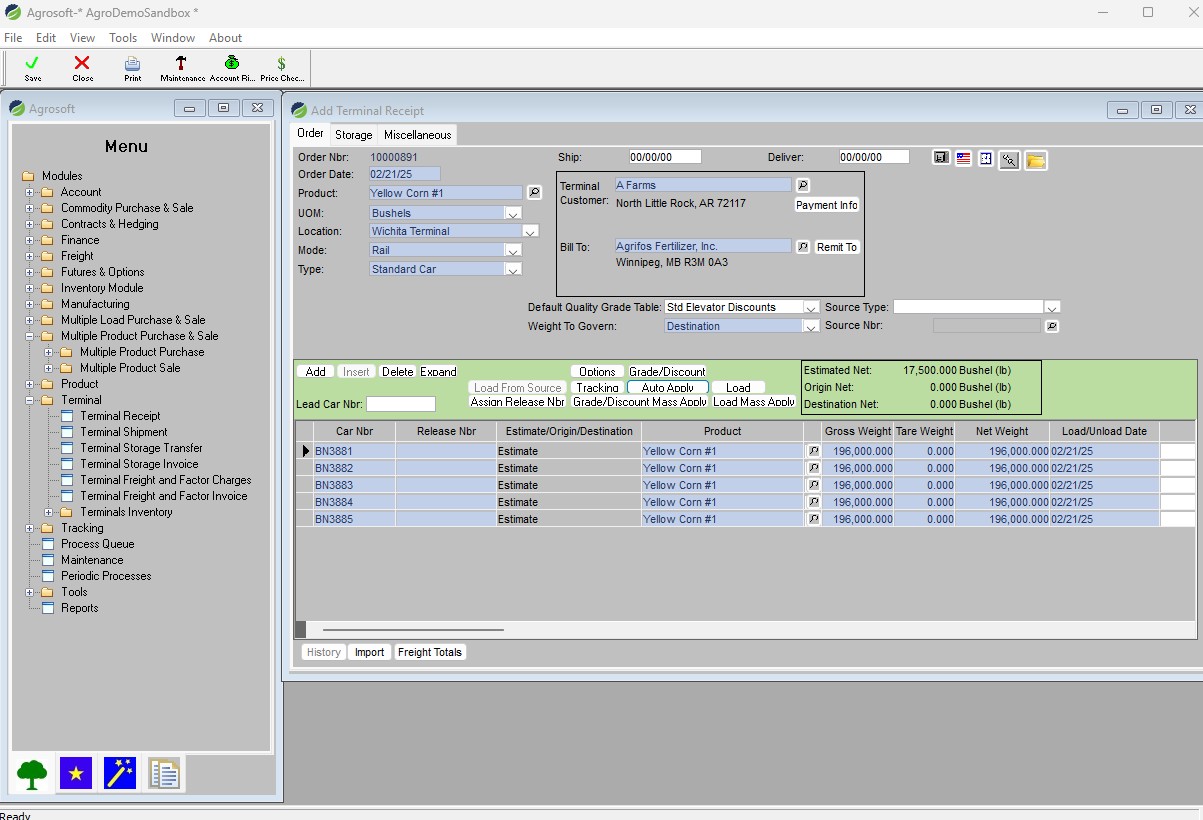

Agrosoft Terminal Module

Agrosoft’s Ag Accounting Software package offers a Grain Terminal Management Software Module, which includes these features:

- Ability to receive grain into a terminal facility, and charge for freight, elevation, drying, or other factors

- Ability to pay a 3rd party for services such as freight, transloading, or stevedorin

- Ability to compute and invoice for storage on a regular, user-defined basis.

- Ability to charge storage based on either the gross weight unloaded or the net stored.

- Ability to transfer grain between two customers.

- Ability to purchase the grain in your own facility.

- Ability to purchase grain or sell it into your own corporate “house” account, including full integration with our country elevator grain module.

- Ability to unload grain and ship out via a variety of conveyances, including truck, rail, barge, and vessel.

Agrosoft’s software solutions support your entire business, from crop inputs through grain scale operations and elevator management, through to terminal storage and the final delivery of the grain. The close integration of these modules reduces dual entry and gives you the accurate and timely information you need to manage your business.